You probably have a sewing machine and have already started sewing, but do you still want to know more about sewing machine needles? This guide is for you as it covers most of the questions you might have about sewing machine needles.

Since the guide is quite detailed and lengthy, you can use the table of contents to navigate the specific aspect of sewing needles you want to read about.

What Is A Sewing Machine Needle?

A sewing machine needle is a type of needle used with the sewing machine to stitch fabrics. Thus, sewing needles play a major role in determining how your sewing machine will stitch fabric. You, therefore, need to have a good understanding of different aspects of the sewing machine needle so that your sewing will be of high quality.

This guide gives you a good understanding of sewing machine needles used in all sewing machines since even if different machines might use different sewing needles, the concept is the same.

Parts of A Sewing Machine Needle

A sewing machine needle has ten parts: point, butt, eye, shoulder, long groove, short groove, eye, scarf, shaft, and shank.

Butt

The butt is the first part of the sewing machine needle at the base/top end of the needle. This part is normally shaped in a particular shape to ensure that the sewing needle is easily attached to the needle bar.

Shank

The shank is the section of the sewing machine needle that is linked to the needle bar. The shank is either flat-ended on one side or cylindrical in many cases. Since it is the part of the needle inserted into the sewing machine, it is the thickest part of the needle.

Therefore, to identify the purpose of needles, you should use the shank of a sewing machine needle. For example, needles meant for home sewing machines have a flat and a rounded side, while sewing machines needles meant for industry sewing have shanks that are either round, threaded, or grooved.

Shoulder

The shoulder is the part of the needle between the shank and blade. For the last few years, different needle manufacturers have been using color coding on the needle shoulder to identify the sizes and different types of needles easily.

The shoulder normally has two different roles for the needle. The first role is that when the needle pierces the textile, and it’s at its bottom point, the shoulder follows the needle and gets into the fabric. Then, through that, it enlarges the size of the hole pierced by the head.

The other role of the shoulder is that when the needle gets out of the textile being sewn with the needle thread, there is usually minimal friction between the needle and the textile because of the large hole. Thus, the shoulder comes in handy as it assists in making sure that the blade of the needle is firmed up.

Blade

The blade of the sewing needle is the section of the needle that is protracted from the eye of the needle to the shoulder of the needle. It is also referred to as the shaft and is crucial in determining the size of the needle. It is mainly the longest part of the needle and the part that comes in the longest close contact with the fabric being sewn.

Long and short groove

The long and short grove is usually along the side of the needle, proceeding to the eye of the needle. The main role of the grove is to offer sewing thread a space to lie as it proceeds to the eye of the needle. A short groove is needed for a normal sewing thread, while a long groove is needed in the needle for a heavy sewing thread.

Sewing Needle Eye

The eye of the sewing machine needle is the part that is at the end of the needle and has a hole. Its purpose is to ensure that the needle has a thread so that the sewing machine can sew on the fabric. There are different sizes and shapes of the needle hence the reason you need to understand the needle you need for the fabric you are sewing.

Scarf

The scarf of the sewing needle is above the eye of the needle. The role of the scarf is to ensure that the hook is set close to the needle so that it can hold the needle when the thread is being looped.

Point and Tip

These two parts are usually at the bottom of the sewing machine needle, and they are usually different in various types of needles used in different types of materials. For instance, when sewing on canvas or leather materials, a very sharp point is needed so that the needle can pierce through the material without causing any damage easily. On the other hand, when the material being sewn is elastic, the needle used would have a tip that is not very sharp.

How A Sewing Machine Needle Makes A Stich

For a sewing machine needle to make a stitch, all the different parts of the sewing needle cooperate.

To begin with, the needle starts by piercing the fabric and goes on to the lowest part that it can get to. It is important to note that the needle usually has a thread in it at this time. When getting on its way back (upward), the needle pushes a loop of thread from the scarf side.

This occurs since the groove on the other side of the needle permits the thread to slip even though the thread does not have anywhere to go. Thus, the thread is pinched among the needle and the textile. During the pinching, a loop is created, and the hook of the bobbin shuttle quickly holds the loop.

As the shuttle goes round, the loop is pulled on the top of the thread entirely around the thread from the bobbin. Thus, the stitch is completed when the needle is pulled out of the textile, and the thread is also pulled up.

Now that you understand the different parts of the sewing machine needle and how the needle ends up stitching a fabric, you are in a better position to select the needle that will be perfect for your next project.

Types Of Sewing Machine Needles

You must understand that irrespective of your sewing machine brand, the needles used by the machines are identical and can be used in different brands of sewing machines. There are seven main types of sewing machine needles.

Universal Sewing Machine Needles

These types of needles are the ones that are commonly used in many sewing projects. The needles are used on interweaved fabrics, synthetic fabrics, and women’s fabrics. The fine universal sewing machine needles are used to sew on lightweight fabrics, while universal larger needles are used on fabrics classified as medium to heavyweight. Some sewing threads commonly used with universal needles are silk, polyester, and cotton threads.

Metafil Needles

They have a large eye implying that they are ideal for unique and thicker threads as they can easily get through the eyes of these needles. They are perfect for most domestic sewing and are easy to thread because of their big eye.

Ball Point Sewing Machine Needles

When compared to the universal needles, the tip of ballpoint sewing needles is more rounded, and due to that, during sewing, the needle can push the textile fibers instead of only cutting the fibers through the sewing process. Due to that feature, the ballpoint sewing needles have been preferred when working on most knit fabrics for many years since they ensure that the fabrics are safeguarded from running the stitching could cause that.

Sharps Needles

Sharps needles are used in fabrics that are heavily woven. Their strong shaft makes them perfect for those types of fabrics as they can pierce through a piece of fabric and yet give an appealing result. The sharps needle also has a threading eye that is round in shape. The shape is crucial in sewing as it provides added strength during the actual sewing.

Quilting Needles

Like the sharps needles, the quilting needles have been developed to sew on fabrics with a few layers of textile and wadding. Nevertheless, as far as the length of these needles is concerned, it can be noted that they are longer than the sharps, and due to that, they make it possible for those quilting to be able to sew at high speeds.

Stretch Sewing Machine Needles

One of the notable features of the stretch sewing machine needles is that they have a scarf that gives additional space for the hook to go through while at the same time ensuring that skipped stitches do not emerge. Therefore, this category of needles is important when one wants to sew complicated materials with high elasticity features.

Jeans/Denim Needles

Just as the name suggests, Jeans needles are specifically meant for jeans. However, the needles are also used in other fabrics that are densely woven, for instance, canvas and heavy-duty linen.

Leather Needles

They are also referred to as chisel point needles due to the point which resembles a chisel. They are purposed to be used with real leather, sued, and other fabrics that are hard to sew. It should, however, be noted that the needles should never be used in synthetic leather or suede.

Wing Needles

They are used together with special stitch features on the sewing machine. These needles make holes in the textile to imitate the drawn thread work. They are ideal for natural textiles such as linen, wool, silk, and cotton.

Embroidery Needles

They are needles that are specifically meant for embroidery. In that view, these needles are characterized by large eyes as they need to permit large embroidery threads to go through the eye.

Top Stitch Needles

They are needles that have a very sharp point so that they can easily penetrate different types of fabrics. In addition, to ensure that they can work with different types of sewing thread, the top stitch needles have a big eye.

Twin Needles And Triple Needles

As their name indicates, the twin needles have two needles in one needle, while triple needles have three needles in one needle. The common feature of these needles is that they have one shank despite having more than one needle eye. They are mainly employed in making decorative stitches and pin tucking. It is, however, important that you confirm whether the sewing machine you are planning to buy can accommodate these needles since not all machines can use twin or triple needles.

Sizes of Sewing Machine Needles

Mainly sewing machines are categorized according to their thickness and purpose.

Thickness

The size of sewing needles differs by the thickness of the needle. Normally, thicker needles are ideal for thicker fabrics, while thinner needles are considered ideal for thinner fabrics such as fairy feathers and chiffon.

Purpose

The purpose entails how the needle is to be used. For example, a needle used in leather cannot be the same as a needle used in silk as various fabrics and various purposes require different needles.

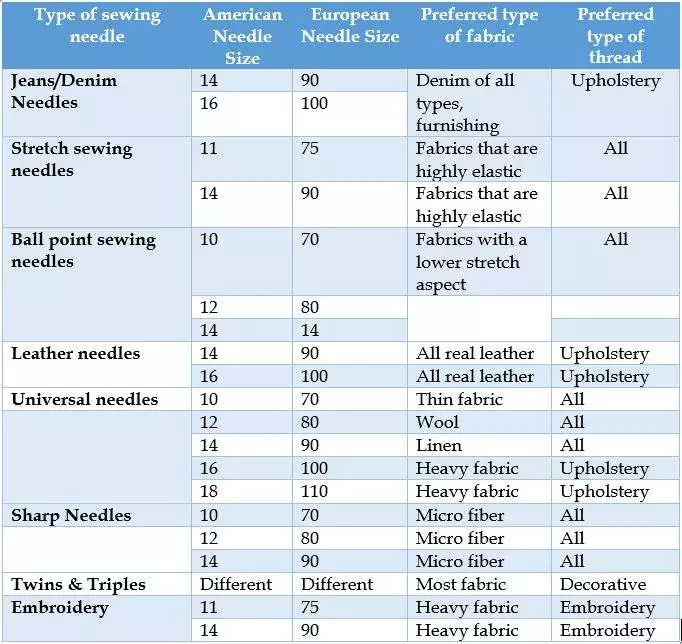

A detailed guide for different needle types, sizes, types of fabric, and thread types has been featured in the table below. It is important to note that American needle size varies from 8 -to 10 while European needle size varies from 60 to 110.

How Often Should You Change Your Sewing Machine Needle?

After sewing for five to eight hours or after using a minimum of three bobbins of sewing thread, you should change the sewing needle. Moreover, when you embark on a major sewing project, you need to make sure that you have changed the sewing needle.

You should also change the sewing machine needle if:

- Your needle is broken or deformed

- When your machine is jammed, and you have noted that the sewing machine needle causes the issue

- When you have changed the fabric to be sewn – for example, when you were sewing a soft fabric but want to sew a denim

- When you have changed the sewing thread – for example, when you will use a thicker sewing thread and the thread cannot fit in the eye of the needle that has been used before

- When you want to do embroidery, the needle in the machine is not an embroidery needle.

How To Change Your Sewing Machine Needle?

Changing the needle of a sewing machine is a straightforward process that anyone can do, irrespective of whether you are a beginner or whether you have been sewing for a decade. Here is a process that would work with most the sewing machines:

i. Identify the needle set screw and make sure that you have unscrewed it

ii. After unscrewing the needle set screw, gently pull the needle downwards and get it out of the needle bar

iii. Replace the old needle with a new needle by pushing the new needle upwards till the point where the needle butt cannot go any further

iv. If the sewing machine you are using is heavy-duty, you will need to make sure that you turn the needle so that the scarf of the needle will be on the same side as the hook part of the machine

v. Proceed to tighten the needle set screw

Is Sewing Machine Needle Magnetic?

No, sewing machine needles are not magnetic. Moreover, hand sewing needles are also not magnetic.

It is, however, important to point out that the majority of sewing needles are mainly made of stainless steel, which is an alloy of iron. Thus, iron has magnetic features means that when the sewing needle comes into contact with anything magnetic, the needle will show some magnetic features.

For sewing needles mainly made of austenitic stainless steel (which does not have any magnetic aspect), the needles might still be attracted to magnetic objects since these needles are coated with Nickel, and this type of coating is known to be highly attractive to magnets.

How To Set Up For Sewing After Changing Sewing Machine Needle

After changing the sewing machine needle, you will need to set up the machine again to continue with your sewing. Here are the steps you have to follow:

a) If you had removed the presser foot during needle change, make sure that you put it back.

b) Thread the sewing machine needle. When threading, you must ensure that the thread comes from the front of the sewing needle’s eye and goes to the back of the eye.

c) You then pull the thread so that it goes under the presser foot heading to the back

d) That’s it, you are set for sewing after a needle change.

If your sewing machine is somehow advanced and has an automatic needle threader, all that you need to do is to make sure that the sewing needle is placed in the precise position so that the needle threader will easily come into contact with the needle’s eye and thread it.

If you are unsure how to use the automatic needle threader function, you can easily thread the needle by hand and get back to sewing.

Sewing Machine Needle Heating

When sewing with your sewing machine, you might realize that the sewing machine needle is heating up. If nothing is done, the heating needle could damage the fabric you are sewing. Let’s now look at how the sewing machine needle heats and how to solve the issue.

The issue of sewing machine needle heating is mainly common in industrial sewing machines that hit very high sewing speeds. For example, industrial sewing machines have the capability to sew at top speeds that vary from 3500 stitches to more than 10,000 stitches a minute.

On the other hand, in most industrial sewing projects, the products that are sewn comprise apparel and non-apparel items, and as such, the sewing threads used are mainly synthetic. Although the synthetic threads are mainly made through a melt-spinning process, they can be damaged to the point of getting melted if the needle heats to the point where it is hot than the melting point of the sewing threads.

As the fabrics sewn on industrial levels comprise synthetic fibers, these fabrics also end up being affected by the extreme heat produced during high-speed sewing.

Apart from touching the sewing needle by hand and finding that it is hot (not advisable), there are other indicators that the sewing needle machine is heating. For example, if your needle is heating up, your will notice that you will experience increased cases of sewing thread breakage. Moreover, there will also be visible damage to the fabric you are sewing.

When you inspect your sewing thread and find that the thread breaks when you stop sewing, and a hard nodule that looks as if the thread has been burnt exists at the end of the thread, that is a clear indicator that the needle is heating up.

How To Reduce Heat On The Sewing Machine Needle

1. Use coated sewing thread – for many sewing thread manufacturers making sewing threads for industrial use, the threads are usually coated with a thread lubricant (not visible) aimed at offering the thread ideal frictional factors will be an equal balanced stitch.

2. The needle used in all sewing projects should have a small diameter since the small diameter has minimal surface areas, and as such, it will minimize needle heat.

3. To address the piercing resistance that some fabrics might have on the sewing needle, the sewing machine needles should be made with strong materials. For example, sewing machine needles with a diamond should be used when sewing leather, canvas, and other fabrics that are quite strong.

4. You should use a ball eye needle. These types of needles normally have a diameter that is bigger than the blade, and as a result, these needles are capable of reducing the heat.

Concluding Remarks

When sewing, needles play a major role in determining your results. Therefore, you must make sure that you are using the right sewing needle and thread to have a good result. If you are unsure of the needle you should use in your sewing; you can use this sewing guide to determine the ideal needle.